Advanced waste processing technologies around the world

Advanced waste processing technologies around the world

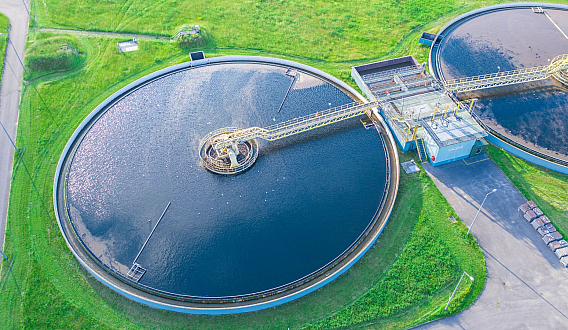

According to information from the Department of Natural Resources and Environment, Ho Chi Minh City is currently prioritizing the shift from burying waste to burning it for disposal. The goal by 2020 is to reduce the amount of buried waste from 76% to 50%, and by 2025 only 20% of waste will be buried.

The odor emanating from the Da Phuoc waste treatment site is a wake-up call for Vietnam regarding waste management. Compared to the advanced technologies and processes in Sweden, Austria, Belgium, or Japan, burying waste is the least effective method of waste disposal.

Burying waste is no longer suitable

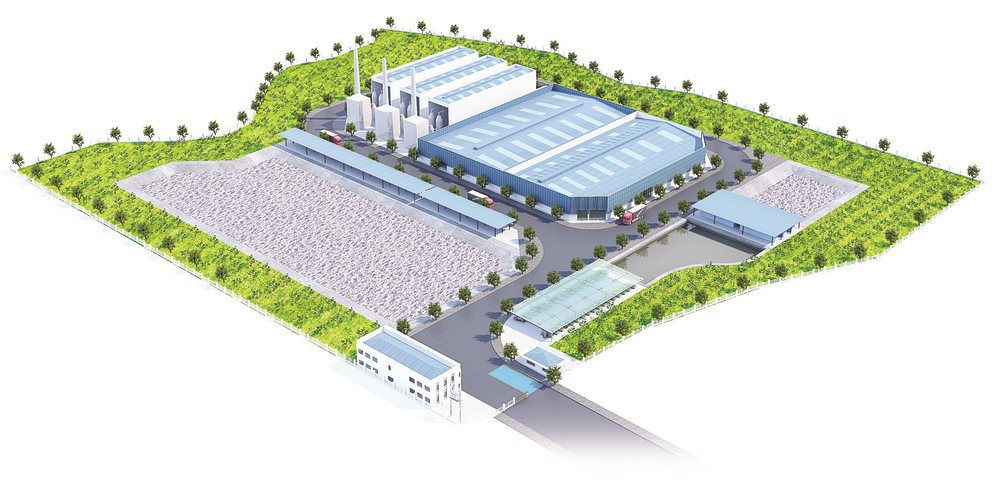

Every day in Ho Chi Minh City, there are 8,900 tons of household solid waste, 5,000 tons of which are transported to Da Phuoc for burial. After 11 years of operation, Da Phuoc has buried 13 million tons of waste with a height of 27 meters - more than half of the estimated amount of waste (24 million tons) for the landfill.

Recently, when the southwest wind blew strongly, the foul odor from the landfill spread to Phu My Hung and neighboring areas, making it unbearable for residents to live there. This is a problem that experts and administrators in Ho Chi Minh City are struggling to solve.

Therefore, in addition to addressing the odor by increasing the use of chemicals, arranging the processing and reception time reasonably, and not concentrating on reducing the odor at one point in time, it is necessary to quickly find alternative waste treatment technologies.

In history, burying waste is the first and oldest method of solid waste disposal used by humans, applied since 320 BC. However, nowadays, burying waste is considered outdated and ineffective.

Around the world, waste management is also a troublesome issue. However, there are countries that are very successful in waste management, such as Sweden, Austria, Belgium, and Japan.

Sweden - A country that needs to import waste for disposal

The amount of waste that needs to be buried in Sweden accounts for only about 1%. The rest is recycled (47%) and burned to produce heat and electricity (52%).

50% of Sweden's energy consumption comes from renewable energy. They have established a waste-to-energy network to collect electricity, integrated into the national power grid.

In the freezing winter, they also have a network of waste-to-energy plants arranged by district to transmit thermal energy and heat to each household.

To meet the great "demand for waste" in Sweden, the people have been and are following a very scientific waste classification process since the 1970s.

However, the amount of waste in the country is still not sufficient for recycling and disposal plants, so they need to import waste from other countries to maintain the operation of the waste-to-energy plants.

Austria - The country that recycles waste using advanced biotechnology

Austria is a small country that has achieved great success in waste management. The most prominent technology in Austria's waste management system is biotechnology for recycling PET plastic.

While the whole world is struggling with plastic waste - the current PET recycling solutions involve either incineration or low-quality grinding, resulting in poor quality recycled plastic. An Austrian company has developed a high-tech solution, using a type of mushroom enzyme to recycle PET plastic. Under the influence of the enzyme, PET plastic will be decomposed into molecules and can then be easily converted back into high-quality plastic.

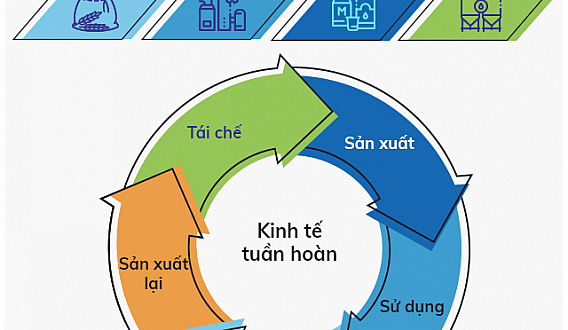

Along with many other advanced technologies, Austria, Belgium, and Germany are currently the top 3 most efficient waste recycling countries in the world.

Belgium - The country with waste management systems in place before being discharged

75% of Belgium's waste is reused, recycled, or composted - the highest percentage in the world. Their resources seem to be reused indefinitely.

They have two extremely advanced waste management processes: Ecolizer and Green Event.

Ecolizer is a web-based system to manage production, ensuring low and clean waste. The system calculates the production process, transportation, consumption, energy, and waste treatment, helping manufacturers evaluate the environmental impact of their products.

From there, proposed improvements in the process and product design, reducing the bad effects on the environment.

With just a small change in design, we can significantly reduce the amount of material and waste. For example, when you need to carry a cup of coffee, using a T-shirt plastic bag will save and protect the environment several times more than a regular plastic bag. And when the number of coffee cups reaches millions, the amount of plastic needed to produce and dispose of in the environment will be greatly reduced.

Green Event is also a web-based management system similar to Ecolizer but for events. This system helps evaluate the amount of waste that an event can generate, ways to reduce waste in the event, and even a list of places to rent reusable scissors.

They do everything to reduce waste from inside the egg water.

Japan - The most efficient country in waste incineration

Compared to European countries, Japan is not the leading country in waste recycling. However, they are at the forefront of efficient waste sorting and treatment.

Japan's waste management is deeply organized. It starts from the awareness of waste sorting and proper disposal by citizens. It then goes through incineration using the CFB technology (Circulating Fluidized Bed).

This technology processes waste by burying it under a layer of sand, and then using the airflow in the furnace during combustion, along with some other chemicals to destroy the waste. The waste inside the furnace will be continuously circulated, and will be completely destroyed in a very short time, even the toughest materials.

Not only that, this technology also reduces the amount of exhaust gases such as NO and NO2 significantly, and is cheaper than other types of waste treatment. The thermal energy generated after incineration is also used to produce electricity.

Simple, efficient, and not too complicated, this technology is now being imported by many countries around the world such as China, Thailand, and Singapore.