Prioritizing Clean Technology Development in Vietnam's Textile and Dyeing Industry

Prioritizing Clean Technology Development in Vietnam's Textile and Dyeing Industry

According to the latest research by the Energy-Efficient and Effective Use of Science and Technology Association (VECEA) on the machinery usage and environmental protection in Vietnam's textile and dyeing industry, the sector had 1,335 enterprises in 2016, an increase of 334 compared to 2010. The industry's overall growth rate averaged 8.66% per year.

![]()

In the years 2018-2019, VECEA conducted surveys in textile and dyeing enterprises. The results indicated that the proportion of dyeing equipment in enterprises over 17 years old (before 2000) was 12.8%, equipment under 10 years old accounted for 34%, and equipment under 7 years old represented 36.2%. This suggests that outdated, low-productivity, environmentally polluting equipment has been phased out, replaced by newer machinery.

The study also revealed that Vietnamese units in the textile and dyeing sector utilize all three types of dyeing processes: batch, continuous (roller), and continuous. In the batch dyeing process, equipment with a liquor ratio of 1:10-1:15 comprises the majority, around 70%. Equipment with low liquor ratios of 1:2.5-1:8 accounts for 26%, and the remaining 14% has high liquor ratios of 1:20 and above.

With 70% of equipment having liquor ratios of 1:10-1:15, the water consumption and wastewater discharge during the dyeing and finishing processes remain significant. This leads to increased costs for water treatment, chemicals, dyes, wastewater treatment, and environmental protection fees for both input and output water, reducing the product's competitiveness and adding economic and environmental pressures on businesses.

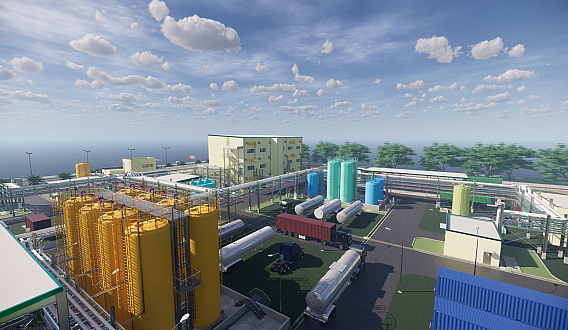

According to statistical data, the entire textile industry discharges an average of about 70 million cubic meters of wastewater annually. However, environmental pollution in the textile industry, particularly in wastewater, is still not tightly controlled in many areas.

![]()

Currently, many enterprises have relocated to centralized areas with modern wastewater treatment facilities. However, the number of textile-dyeing factories in these areas is still limited, with just over a dozen businesses certified for environmental management according to ISO 14000 standards. Most remaining enterprises still employ basic wastewater treatment methods, and post-treatment wastewater still contains a significant amount of environmentally harmful pollutants, especially in craft village industrial zones.