Benefits of automation in modern manufacturing

Benefits of automation in modern manufacturing

There are many factors that influence the automation process of a country or industry. Some important factors include digital technology, human resources, and capital resources. To ensure a smooth automation process, it is necessary to understand the nature of automation in each field and production process, and apply it optimally to increase productivity and reduce costs.

Benefits of automation in modern manufacturing

1. Significantly increase production productivity

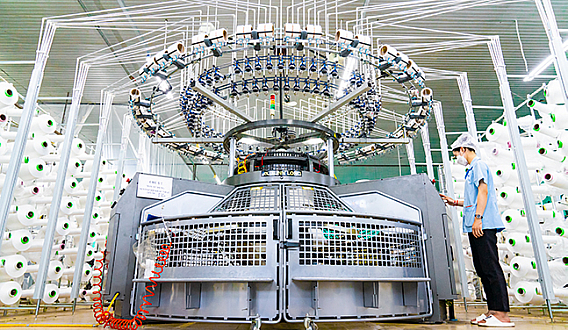

Thanks to automation, machines can operate 24/7 without rest or breaks, unlike human labor. Moreover, the operating speed of automatic assembly lines is much faster than manual operations. Therefore, factories can significantly increase production productivity. This is considered the primary and most obvious benefit of any factory that applies automation.

2. Reduce labor costs

The application of automation in production means maximizing the participation of automatic machines and minimizing the participation of humans in the production process. Therefore, businesses can reduce labor costs. Instead, they only need to invest in production once, which is a smart and effective investment. Furthermore, there are many dangerous stages in production if humans are directly involved. Therefore, thanks to automatic assembly lines, labor safety at factories can be guaranteed.

3. Improve product quality and reduce raw material costs

When the production process is automated with programmed parameters, the resulting product will always have high accuracy and low error rates. Automation helps businesses minimize the errors related to human workers. Furthermore, with automated production lines, products always have the highest level of consistency. Low error rates mean that factories can reduce raw material costs and production costs related to fixing faulty products or producing replacement products.

4. Enhancing workforce skills

The application of automation in production will provide opportunities for businesses to shift their workforce to more proactive positions and train them to quickly access technology. Instead of doing manual work, they will now be able to enhance their skills to operate machinery to assist in those tasks. Therefore, this helps the workforce specialize and quickly access modern technology.

5. Bringing maximum flexibility in production

This is considered a very clear benefit of automation. Changing processes, production lines, adding or subtracting stages often takes a lot of time and effort. If automation equipment is not applied, the business will spend time on training employees, changing management, team... However, when automation is applied, only programming is required and the program will have the highest level of customization.

High level of customization: Changing production processes, especially when adding new stages, is often very complex because this work must be accompanied by employee training as well as management changes. For robots, the program will ensure the ability to perform all assigned tasks. This will increase the level of customization in production.

6. Improving competitive position for businesses

Increasing productivity, cutting raw material costs, and labor costs will help manufacturing plants reduce costs. Meanwhile, product quality is significantly improved, which helps businesses improve their competitive position in the market. Applying automatic production lines will help businesses make breakthroughs in production and business. Of course, in the condition that the business knows how to apply them appropriately.

Popular Applications of Automation

- With the clear benefits mentioned above, automation has been and is being applied in many different fields and achieving significant achievements. Thanks to the development of the Internet and the fourth industrial revolution, automation is considered a key factor to help businesses develop and improve their competitive position in the market. Typical fields that are applying automation technology and equipment include mechanical engineering, compressed air, healthcare, agriculture, electricity, electronics, automobile manufacturing technology, and ships.

- Especially in mechanical processing, if according to traditional methods, mechanics had to manually process or use automatic machines such as lathes, milling machines, welding machines, etc., then thanks to the application of automatic equipment, automatic robots have performed these stages with modern processing machines, programmed by CNC. Or dangerous stages such as welding are maximally assisted by modern welding robots. Especially, the CAD/CAM/CNC technology has helped the processing process operate according to a closed process, with high speed, and almost absolute precision.

- In the food and beverage industry, many restaurants have used mobile phones and tablets to apply ordering processes to make them faster and more efficient. Meanwhile, the mining industry is also applying a lot of automation, such as in mining. Or automatic interior vehicles such as automatic rolling doors, hospital lead doors... In addition, in factories producing appliances, food, many automatic conveyor belts are applied in the production line, helping to control quality as well as operating the production cycle, installation, packaging, and shipping more quickly and efficiently...

Industry 4.0 on the basis of automation

Thanks to the achievements of the industrial revolution, especially the strong development of the Industrial Internet of Things (IIoT), the application of automation in production is increasingly being focused on and rapidly promoted. Many businesses were initially concerned that investing in new production technology lines would cost a lot of money and training personnel to use them would take a long time. However, the reality is that the result of the Industry 4.0 revolution has helped production businesses solve economic problems and invest intelligently and efficiently.

In the face of the new wave of digital technology, the application of high-tech production lines is imperative. Smart factory models are being developed to meet the increasing demand of customers for the highest quality and most sophisticated products.

In the industry, prominent trends include multitouch sensors, wireless connectivity, and robotics. Among these, robotics is the most popular trend. Initially, robots were just devices that performed simple activities such as moving objects and lifting weights. However, nowadays, robots are controlled by intelligent software and programmed to perform many complex operations, meeting the increasingly high demands in the production process of factories.