Notes when investing in building electronic, microchip manufacturing factories

Notes when investing in building electronic, microchip manufacturing factories

Building an electronics and microchip manufacturing plant is a top priority for production companies. This is completely understandable as the issue of microelectronics is currently receiving much attention and emphasis. In the context of the world's shortage of microchips, manufacturing in an environment that ensures clean standards is essential. So what are the considerations when investing in building an electronics and microchip manufacturing plant? Let's find out in this article!

1. Standards for electronics and microchip manufacturing plants

1.1. What is an electronics and microchip manufacturing plant?

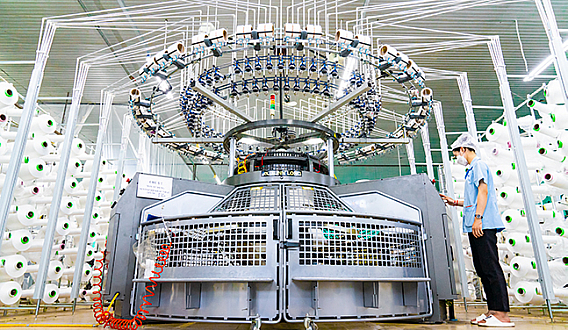

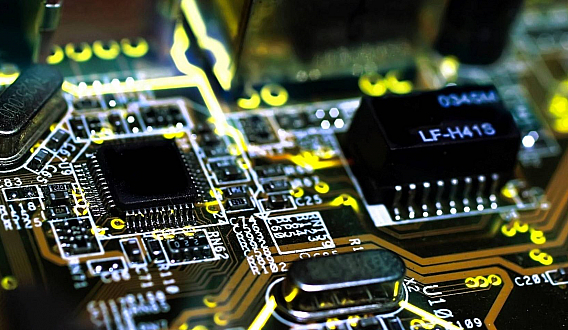

Electronic components, circuit boards, or more simply, the mobile devices we use today are manufactured on extremely modern and sophisticated assembly lines. However, a few tiny dust particles or incorrect humidity levels in the manufacturing location can cause a large number of defective products that have not been checked before being shipped out.

In an electronics and microchip manufacturing plant, the production process is divided into different areas or rooms. Due to the high cost of investing in a clean room, only the production areas that require a high level of cleanliness are equipped with clean rooms.

The production areas that require high cleanliness and strict manufacturing standards must be built with clean rooms. These areas include:

- Direct production and assembly area: Products must not have any dust particles and the humidity level must be kept within acceptable limits.

- Research and product development area: This process is also considered to be of equal importance to production as the research products also require precision.

1.2. Cleanliness level standards for electronic and microchip manufacturing plants

When a complete location for constructing a cleanroom is planned, an equally important aspect is to ensure that the construction and installation of the cleanroom meet the standards of the electronics and circuit manufacturing industry, in order to achieve the best results during the production process.

1.2.1. Standard temperature for cleanrooms in electronic and microchip manufacturing plants

According to standards, the average temperature inside a cleanroom should range from 20-26 degrees Celsius. This temperature range ensures the safety of electronic devices, microchips, and electronic components. Failure to maintain this temperature range will result in unstable battery operation and melted solder or connections.

1.2.2. Standard humidity for cleanrooms in electronic and microchip manufacturing plants

On average, the humidity inside a cleanroom in an electronics and microchip manufacturing plant should range from 18-55%. However, not every room will maintain this temperature range. Based on the complexity of electronic components and circuit boards and the expertise of engineers, the humidity level needs to be adjusted appropriately to suit the product. If the humidity is too high, the components will become waterlogged, which will greatly affect the production process and result in increased costs.

1.2.3. Requirements for cleanliness and microbial standards in electronic and microchip manufacturing plants

Cleanliness and microbial standards in cleanrooms are always limited to the lowest level or, in other words, no presence, to ensure maximum production of electronic products.

1.2.4. Standard pressure for cleanrooms in electronic and microchip manufacturing plants

The standard pressure inside a cleanroom should range from 15-45 Pascal.

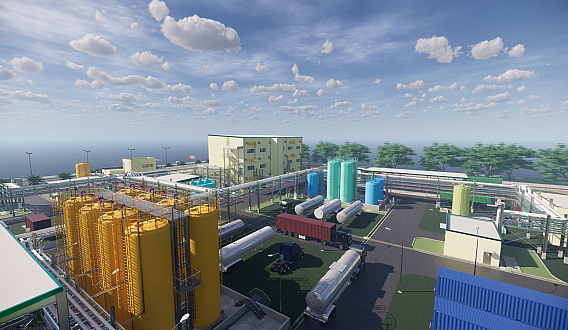

2. The steps and considerations when investing in building an electronic and microchip manufacturing plant.

When starting to build an electronics and semiconductor manufacturing plant, there are many important factors that business owners need to consider, including the steps and considerations involved in investing in the construction of such a facility.

- Location and building area of the clean room

- Choosing the corresponding cleanroom level

- Choosing suitable materials with reasonable cost

- Appropriate construction plan

- Reliable and experienced cleanroom construction contractors

- Reputable and high-quality cleanroom equipment suppliers.

The above are the standards, steps, and considerations involved in investing in the construction of an electronics and semiconductor manufacturing plant. Meeting these requirements or standards is a significant achievement for businesses that are currently implementing the construction of such a facility.