Greening" the textile industry with natural dyeing?

Greening" the textile industry with natural dyeing?

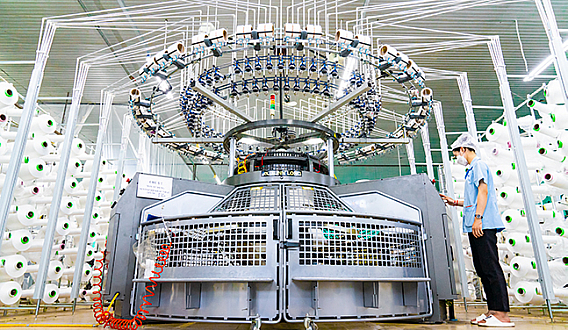

Every year, the wastewater discharged into the environment by the entire textile industry amounts to 70 million cubic meters - equivalent to the capacity of a small hydropower reservoir. According to the Vietnam Cotton and Spinning Association, the cost of production techniques and wastewater treatment systems makes the investment in dyeing and finishing technology seven times higher than the investment in textile production, leaving investors hesitant. As a result, when it comes to dyeing enterprises, local doors are cautiously closed, while the global doors for the entire textile industry face numerous obstacles.

Faced with environmental pressures, many researchers are seeking ways to "green" the textile industry, on the principle of going against synthetic chemicals and returning to the use of natural materials for dyeing. Tea leaves, sedge leaves, sappanwood bark, or cashew nut shells are abundant raw materials in Vietnam that can be used for dyeing fabric. This is a method for natural dyeing applied on an industrial scale. The wastewater, in this case, is mainly tea water, and tea waste is reversed to become organic fertilizer.

Although small-scale and showcase-oriented, such initiatives, while interesting, lack widespread dissemination. Like many other inventions, the experimental effectiveness, when transitioning to industrial production, proves to be challenging, leading to slow progress and small-scale implementation.

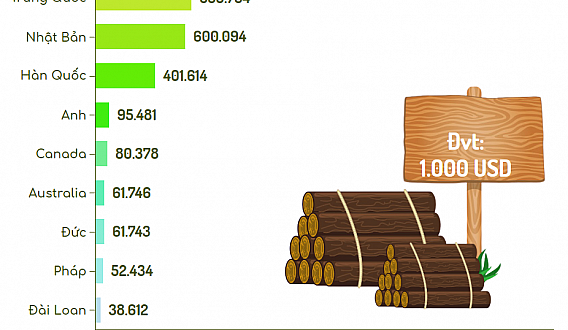

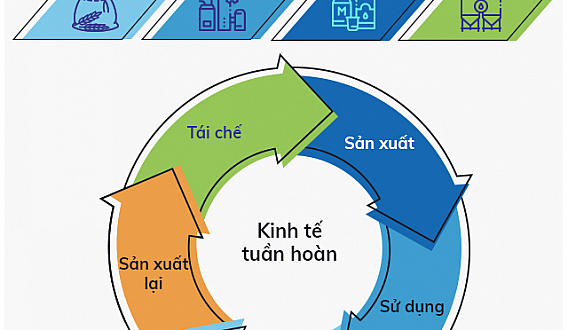

Currently, with the trend of sustainable development, plant-based dyeing is being applied in all areas of textiles, fashion, and cosmetics in this country. This has created a market worth nearly USD 1 billion - with just one type of plant. It is a way to "green" the textile industry, transforming awareness into long-term economic value worth considering.