Strategy for the development of Vietnam's chemical industry

Strategy for the development of Vietnam's chemical industry

Strive for a growth rate of the chemical industry sector from 10-11%/year

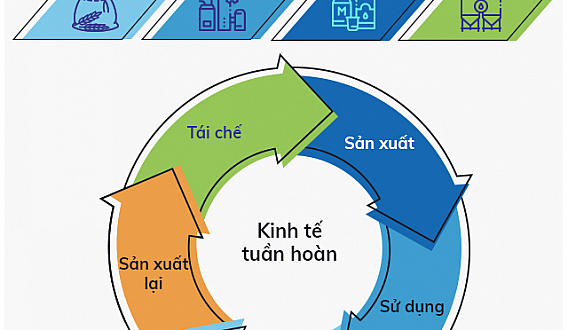

The Strategy for Development of Vietnam's Chemical Industry until 2030, Vision to 2040 (the Strategy) aims to develop a chemical industry that is fast-growing, sustainable, modern technology-driven, environmentally friendly, and geared towards green growth and circular economy.

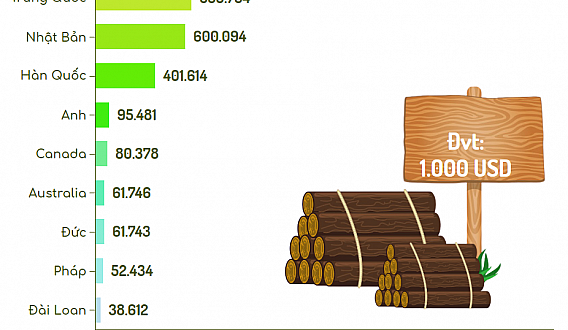

The Strategy sets a target to strive for an average annual growth rate of the chemical industry sector at 10-11% and a proportion of the chemical industry sector compared to the total industrial sector at around 4-5% by 2030.

By 2040, the average annual growth rate of the chemical industry sector is expected to be around 7-8%, while the proportion of the chemical industry sector to the total industrial sector is expected to remain at around 4-5%.

Specifically, the group of products including petroleum, pharmaceuticals, technical rubber, and basic chemicals is expected to achieve a growth rate of 10-12%/year during the period of 2021-2030, and an average growth rate of 8-11%/year during the period of 2031-2040. Meanwhile, the group of products including fertilizers, plant protection chemicals, electrochemical power products, cleaning products, industrial gases, tire raw materials, and ink and paint products is expected to achieve a growth rate of 3-5%/year during the period of 2021-2030, and an average growth rate of 4-6%/year during the period of 2031-2040.

By 2030, the industry aims to maintain the level of meeting domestic demand for common products such as urea, phosphate, NPK fertilizers, plant protection products, tire raw materials, industrial gases, common ink and paint products, cleaning products, and common batteries, as well as developing the export market. The industry also aims to partially meet the domestic demand for ammonium sulphate fertilizers. The industry plans to increase the domestic supply capacity for common products such as petroleum products to 40%, plant protection agents to 30%, basic chemicals to 70%, technical rubber to 40%, and batteries to 75%.

Develop the chemical industry towards a modern and foundational industry

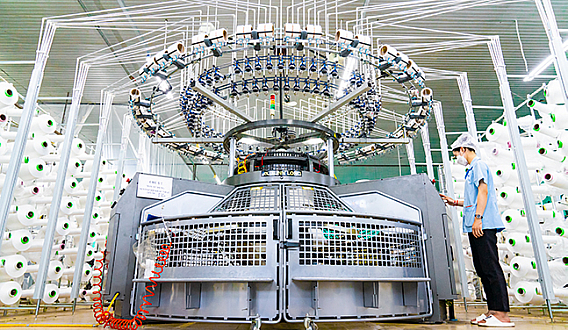

According to the strategy, the chemical industry in Vietnam will develop towards a modern and foundational industry with a relatively complete industry structure consisting of 10 sub-sectors: fertilizers, plant protection products, pharmaceuticals, petrochemicals, basic chemicals (including precursor explosives and industrial explosives), rubber products, electrochemistry, detergents, paints and inks, and industrial gases. Among them, the focus is on developing some key sub-sectors: basic chemicals, petrochemicals, technical rubber, pharmaceuticals, and fertilizers.

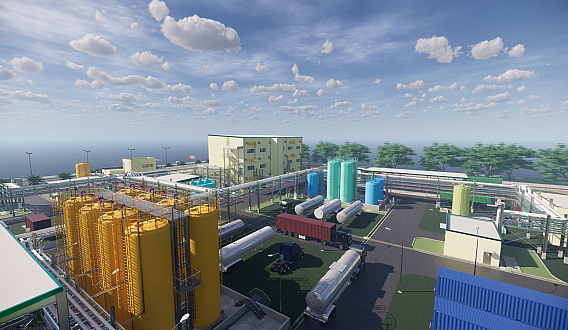

Reorganize existing production facilities towards concentration and scale; maintain and develop production plants with advanced technology; minimize the formation of new and gradually eliminate small-scale production facilities that use outdated technology, have low resource efficiency, poor product quality, and cause environmental pollution.

Promote innovation, restructure and improve the business efficiency of state-owned enterprises in the chemical industry, improve the efficiency of state capital in state-owned enterprises, overcome scattered and ineffective investment.

Shift the policy of attracting FDI in the chemical industry from quantity to quality, with a focus on priority areas and products, projects that use advanced, modern and environmentally friendly technology, bringing high economic and social efficiency.

Develop the chemical industry in a concentrated manner, in line with the advantages of each region and locality, not evenly distributed according to administrative boundaries, ensuring environmental protection, national defense and security requirements. Form and promote the effectiveness of concentrated industrial clusters and chemical complexes with large scale to attract chemical production projects, projects that use chemicals to produce in other fields, chemical logistics centers in locations with large land funds, away from residential areas, near deep-water ports, convenient transportation connection, and encourage circular technologies, products, and waste that are not used by this factory to be used as raw materials for other factories.