4 Effective methods of industrial waste treatment in factories

4 Effective methods of industrial waste treatment in factories

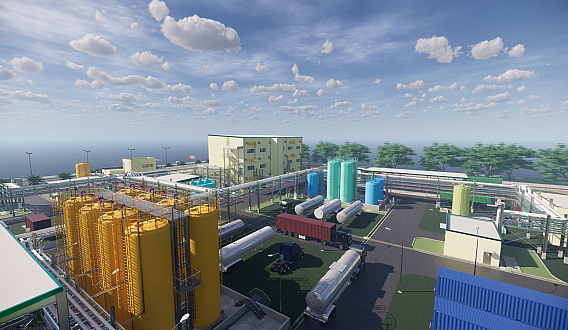

Waste management in factories is an extremely important process that helps ensure the safety of the environment surrounding the production area. To make this process work efficiently, it is necessary to follow the regulations and clear principles. This article shares more about industrial waste treatment measures for engineers and environmental managers to refer to and apply if necessary.

What is industrial waste?

Industrial waste is waste materials with varying levels of toxicity generated from factories, production processes, and business activities such as smelting, manufacturing, and incineration.

Basic process of industrial waste treatment:

Depending on the characteristics of each type of waste, there will be different methods of collection and treatment. Typically, the process of treating industrial waste includes the following basic steps:

Step 1: Manage and quickly treat waste by sorting it at the source of generation.

Step 2: Collect industrial waste that has been sorted:

- Regular waste: placed neatly in designated areas.

- Hazardous waste: choose appropriate containers and label them with hazardous waste signs for identification.

Step 3: Transport industrial waste to a centralized landfill.

Step 4: Carry out industrial waste treatment using suitable methods based on the characteristics and toxicity levels of the waste.

4 effective methods of industrial waste treatment in factories

Currently, there are many different waste treatment technologies. However, to apply them effectively, it is necessary to understand the characteristics and toxicity levels of the waste. Here are 4 commonly used safe treatment methods in factories:

1. Thermal method

-

Using waste incinerators in the form of liquid waste incinerators, cement kilns, steam furnaces... by using heat to destroy waste.

-

The amount of heat generated in this incineration process can be utilized for boilers, heating, and for thermal and electrical industrial applications in the factory.

-

Conditions for application: Waste must be flammable.

2. Safe landfill method

-

The waste treatment technique using the landfill method will minimize the possibility of waste spreading into the environment.

-

The conditions for applying this method are:

Waste with low organic or inorganic content.

100% free from radioactive substances.

Free from infectious or explosive materials.

No liquids and low water leakage ratio.

Especially, no tires.

3. Recycling method

-

This is one of the methods chosen by many factories because it limits the amount of waste released into the environment and creates new products for reuse, bringing practical benefits.

-

Conditions for application: Waste that is difficult to decompose but can be recycled and reused, such as paper, safe metals, and plastics.

4. Biodegradation method

-

This method removes water from the waste to transform it into a porous state in a high air environment to decompose or create new products for use, such as fertilizer and biogas.

-

Conditions for application: Industrial organic waste without toxic properties.

Currently, many factories directly discharge waste into the water environment or do not classify waste, and bury hazardous waste to minimize costs. However, this is a serious violation of the law. Companies may be warned or fined up to 2 billion VND if they deceive during this process. Therefore, environmental management and engineers of the factories need to choose suitable treatment methods above or contact outside partners to ensure the surrounding areas of the factory are always safe and hygienic.