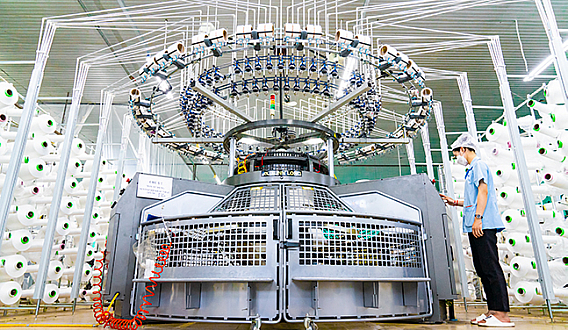

Production management methods at an electronic component factory

Production management methods at an electronic component factory

Production managers at electronic component manufacturing plants communicate the value of raw materials, creating end products that can be used or consumed by end customers. To ensure that customers receive exactly what they want in the way they want it, manufacturers deeply care about the systems and processes related to producing goods at their facility.

What is production management?

Simply put, production management is the process of efficiently managing the resources necessary to turn raw materials into finished products, focusing on the entire product lifecycle. Of course, these resources are varied, including everything from people and materials to various equipment used at facilities.

Why is production management important at an electronic component manufacturing plant?

Because production management focuses on factory-level activities, it is a necessary aspect for manufacturers. Therefore, what is important for a manufacturing business is to pay attention to all related processes. Some key factors as to why production management at an electronic component manufacturing plant is important are as follows:

To reduce production costs

If a production activity uses too many financial resources to produce goods for customers, it may not generate enough profit. In such cases, business operations often become unsustainable, leading to collapse.

Therefore, caution is required for manufacturing business owners in managing production. It can help them analyze their processes to improve optimization. Proper management leads to less input and more output, resulting in reduced production costs and wider profit margins.

To ensure rational and optimal use of resources

Production management in the electronic component industry allows companies to analyze the resources needed in the production process. For example, manufacturers must manage inventory and raw materials, monitor labor force, and supervise equipment and machinery being used in the production process.

This evaluation allows manufacturing companies to optimize their resource deployment, ensuring that they use the right input factors to create the final products. In addition, it helps eliminate waste, making operations more efficient and profitable.

Enhancing competitiveness in the market

In the manufacturing industry, competitors always try to make a mark in any target market. And if your company cannot compete with competitive services, it will gradually lose ground.

Manufacturers carry out production management to ensure that they always produce high-quality products to meet consumer demand. As a result, consistency makes the business better equipped to maintain competitiveness with rivals.

Furthermore, the brand position is increasingly important to consumers, putting the business on a trajectory for greater market presence.

To achieve the set goals and business objectives

As discussed earlier, production management falls under operational management. The latter involves executive-level activities to analyze market situations and identify the objectives and goals that a business needs to meet to maintain its operations.

Production management takes over at the grassroots level to optimize production operations to meet the set goals. With proper management, the organization produces high-quality goods - at lower costs - meeting or exceeding customer expectations.

This improves satisfaction, leading to repeat business and long-term customer value. Such an operation ultimately marks all the boxes set out by the responsible executive operations manager.

Solution for IoT in production management at an electronic component factory

Increasing customization capabilities, higher customer expectations, and an increasingly complex global supply chain are just a few of the challenges that manufacturers face in the race to lead in a highly competitive industry. These challenges have led companies to seek manufacturing management solutions in the electronic component industry. Currently, most factories have switched to using IoT to digitize the manufacturing industry due to the following benefits:

-

Cost reduction by optimizing asset management and inventory management; reducing machine downtime and allowing faster operation and more energy-efficient use.

-

IoT solutions for production create conditions for faster decision-making. This helps manage resources and optimize assets related to both human and machine data.

-

The Internet of Things can help ensure a safer working environment in the manufacturing industry.

Expected results after applying IoT

More intuitive user interface: The visual system helps businesses save the time needed to train employees to use the software. In addition, simple features allow supervisors and managers to easily schedule operations, eliminating the need for regular manual checks throughout the day.

Detailed customization: Electronic component manufacturers can modify their production management systems to suit their individual needs. Digital tools are now specially placed to meet the unique production management requirements of manufacturers.

Comprehensive analysis: Production management requires various types of data, providing managers with the necessary information to make decisions. But with modern factories, an absolute amount of data is generated that needs significant analysis.

The production management system is equipped with powerful analytics that provide detailed information on production status, allowing managers to make informed decisions.

Shared access rights: Modern digital production management tools eliminate traditional and poor methods. Instead, the new cloud-based version ensures that relevant entities can access data from anywhere.