The wood industry calculates personnel and technology for Industry 4.0 production

The wood industry calculates personnel and technology for Industry 4.0 production

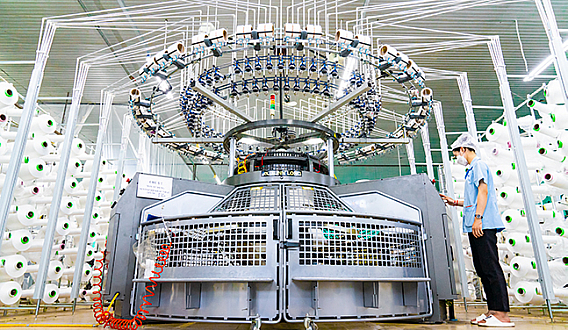

As one of the leading manufacturing and export industries in Dong Nai province and the country as a whole, the Wood industry has the opportunity to dominate the world market through free trade agreements. To exploit the market effectively, the Wood industry needs to enhance its production capacity based on technology innovation and prepare a skilled workforce to operate the technology.

* Businesses need to change beforehand

According to the Provincial Forest Protection Department, there are currently 1,454 wood processing and trading establishments operating in the province, including 904 enterprises and 550 household-scale production facilities. Among them, only 115/904 enterprises (accounting for 12.7%) have factories located in concentrated industrial zones and clusters. These factories are mostly foreign-invested, with large capital scales, modern machinery and equipment investment, and production experience with export-oriented products. The number of enterprises with factories located outside industrial zones and clusters is still relatively high (87.3%). In addition, constraints on production capacity, productivity, technology, and skilled labor also affect the industry's competitiveness.

Regarding production productivity, according to Mr. Le Phuoc Van, Director of Hanh Gia Management Consulting Co., Ltd., Head of the Lean Production Club of the Wood industry in Binh Duong, through training and consulting for more than 170 enterprises in Dong Nai, Binh Duong, Ho Chi Minh City, and some other provinces and cities, he found that wood production in different enterprises currently varies greatly. There are enterprises achieving labor productivity of 30-50 USD, while others have reached 70 USD or even more. This shows that there is still no uniformity among enterprises, and investment in productivity improvement is not the same.

To increase productivity, enterprises need to go through three stages. The first is to invest in equipment, use external forces to increase productivity, the second is to standardize production, standardize resources, and finally, innovation. Currently, most enterprises tend to focus on technology equipment but have not paid enough attention to the other factors, which are decisive because they relate to human factors.

According to Mr. Nguyen Phuong, Vice Chairman of the Dong Nai Wood and Handicraft Association (Dowa), in the context of the booming wood market, especially the opportunity to export to countries such as the United States, Europe, enterprises always need to maintain high levels of quantity and quality production. Changing the thinking of enterprise management, improving production efficiency and applying new technological achievements will be disseminated and supported by Dowa for enterprises and members to actively implement.

* Building a sustainable production plan

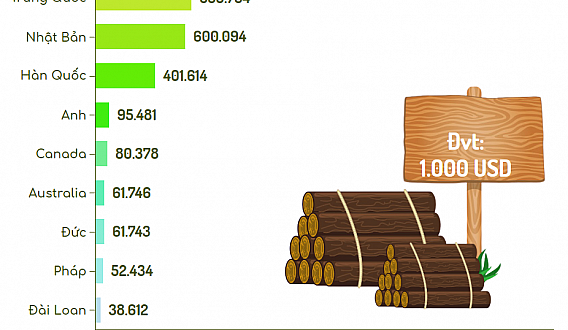

According to Dowa, in 2020, the Wood industry underwent many fluctuations, especially the complex development of the Covid-19 pandemic which greatly affected the global economy. However, Wood companies made every effort and achieved strong growth in both output and revenue. The country's wood and wood product exports reached nearly $12.4 billion, an increase of over 16% compared to 2019. It is estimated that in 2021, the Wood industry will continue to grow by 15% compared to 2020. In Dong Nai province, in 2020, the export turnover of wood products reached nearly $1.7 billion, an increase of over 11% compared to 2019.

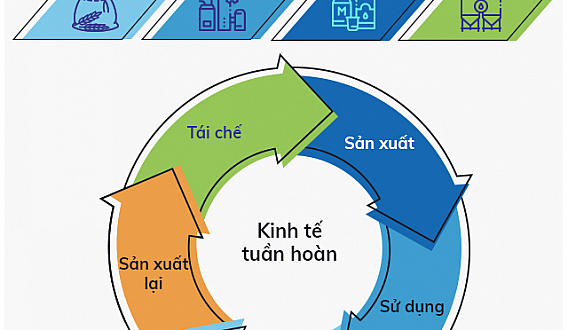

With such good growth, new production workshops and factories are emerging, and many factories are reorganizing production and improving their technology chains. In the context of the Wood industry facing many opportunities and challenges, investing in modern technology, machinery, and recruiting and training high-quality human resources plays a very important role. As the second largest wood production value province after Binh Duong, Wood companies in the province, especially small and medium-sized enterprises, are linking up to form a production chain. From raw material supply, wood imports, machinery and equipment cooperation in production and product consumption. In the future, Dowa will continue to implement programs and solutions to support and promote its member companies to improve their production capacity, improve competitiveness in the market, and maintain their position as one of the province's main manufacturing industries.

To promote the development of the industry, the Sustainable Production and Processing of Forestry Products plan on Dong Nai province's territory by 2025, with a vision towards 2030, has just been approved by the provincial People's Committee. The Wood industry continues to be identified as one of the key manufacturing industries. Accordingly, the province will focus on reviewing, consolidating, and upgrading the small and medium-sized wood processing system, while developing large-scale wood processing industries. It will also build and expand wood processing industrial zones in areas with sufficient raw materials, convenient infrastructure, ensuring profits and competitiveness in the international market.