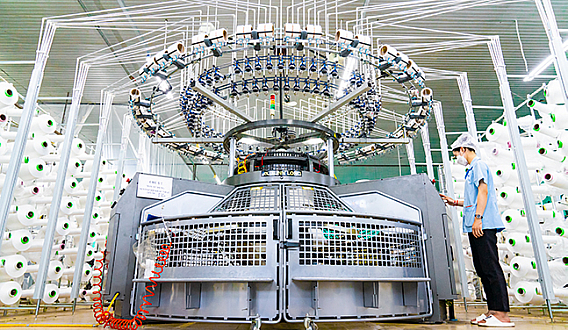

Need Mechanisms to Attract Investment in Textiles and Dyeing to Support Textile Exports

Need Mechanisms to Attract Investment in Textiles and Dyeing to Support Textile Exports

The Vietnam Textile and Apparel Association (VITAS) stated that, in the first 7 months of 2022, the production and business situation of textile enterprises has been favorable, with abundant orders and a gradually stabilizing workforce. The total export turnover of textiles is estimated at USD 26.55 billion, an increase of 16.5% compared to the same period in 2021.

However, Vietnamese textile enterprises are facing fierce competition with countries experienced in exporting textiles to the markets of Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the European Union, such as China, Bangladesh, Turkey, and India.

Importing 80% of fabric for export manufacturing

Explaining this, VITAS stated that the rules of origin from yarn and fabric onwards are weak links for Vietnamese textiles because the country has to import up to 80% of the fabric for export manufacturing.

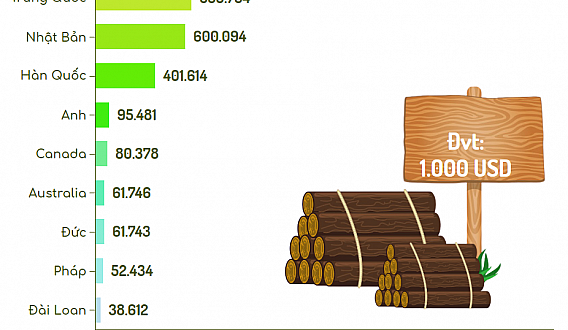

According to VITAS, in the first 7 months, the total import turnover of textile raw materials is estimated at USD 15.48 billion, an increase of 7.9%. Therefore, on average, Vietnam has to spend over USD 2 billion each month to import raw materials, including cotton, fiber, various fabrics, and raw materials for textiles, garments, leather, and footwear industries, mainly imported from China.

The prices of textile raw materials are rising rapidly due to fluctuations in crude oil prices, and transportation costs are high due to fluctuating fuel prices.

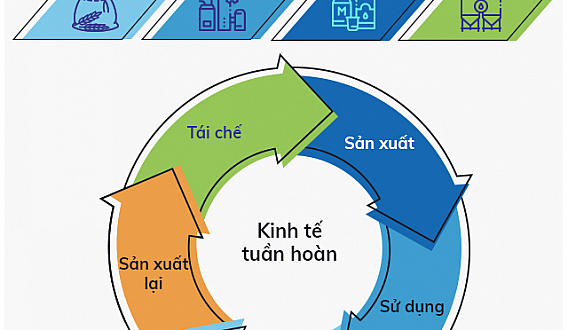

In addition, importing countries are increasingly setting more criteria for products. For example, recently, the Vietnamese Trade Office in Sweden stated that both the EU and other Nordic countries such as Norway and Iceland are demanding that the textile industry develop more sustainably and circularly.

These countries have stricter requirements for natural and synthetic fibers. Woven fabrics must be organic, recycled, or biologically sourced. Cotton used in eco-labeled clothing in Northern Europe must not be made from genetically modified organisms (GMOs) and must be 100% organic or recycled. Higher durability and quality are required, and woven fabrics must be tested to ensure new criteria for durability, such as abrasion resistance, colorfastness, tensile strength, and seam strength.

Facing the "difficult problem" of raw materials, some Vietnamese enterprises are also investing in researching and developing raw materials to serve production, enhancing proactivity to reduce dependence on imported raw materials. However, dependence on imported raw materials still remains high.