The Nam Binh Duong Waste Treatment Complex strives for improvement, ensuring environmental protection and energy efficiency

The Nam Binh Duong Waste Treatment Complex strives for improvement, ensuring environmental protection and energy efficiency

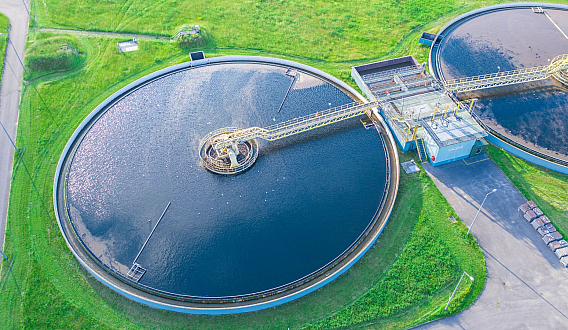

The Nam Binh Duong Waste Treatment Complex (Binh Duong Environment and Water Supply JSC) has made continuous improvements during its operation, effectively treating various types of waste generated in the province and producing many recycled products such as electricity, building materials, and organic fertilizer.

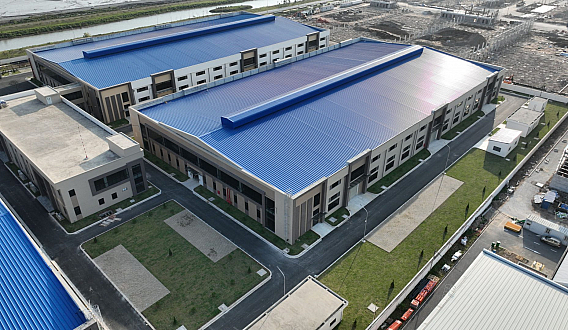

Currently, the total area of the Nam Binh Duong Waste Treatment Complex is 100 hectares, of which the current usage area is 75 hectares, and the remaining 25 hectares have not been invested in construction. The entire 75-hectare area of the complex is divided into 6 main zones and surrounded by existing rubber trees, demonstrating the area of the complex. The Nam Binh Duong Waste Treatment Complex is a shining example throughout the country in the systematic, large-scale, and modern treatment of household and industrial waste. However, the company continues to strive for improvement in order to further enhance and develop.

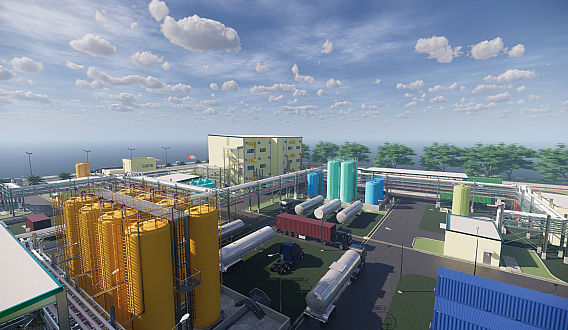

After more than 17 years of operation, the Binh Duong Waste Treatment Complex has completed two phases, receiving a daily amount of 1,200 tons of household waste, 400 tons of industrial waste, and 200 tons of hazardous industrial waste. With a total investment capital of USD 30.5 million and a land value of 100 hectares for both phases of the project, the Binh Duong Waste Treatment Complex has completed modern recycling and waste treatment technologies.

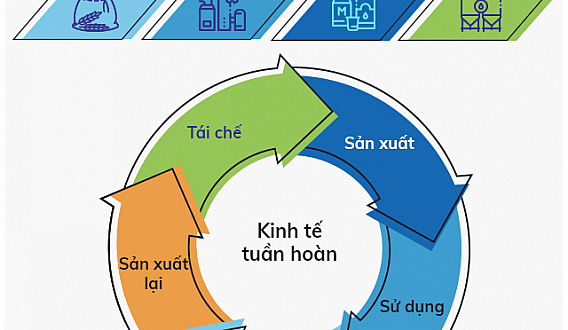

In addition to waste collection and treatment, the Binh Duong Waste Treatment Complex has also invested in many new technologies to turn waste into valuable raw materials for producing valuable products. With a strategic vision for cooperation with domestic and foreign partners, the efforts of the company's leaders and employees, and the philosophy that "Waste is a resource", the factory strives to recycle and utilize waste to both contribute to environmental protection and save costs.

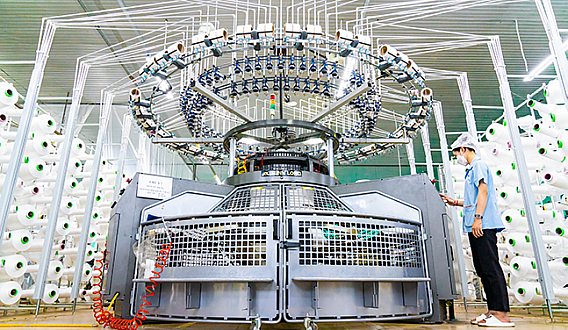

The unit applies a natural lighting system and designs the ceiling with translucent panels to provide efficient lighting for the production area during the day, saving electricity and lighting costs. Due to the nature of the manufacturing industry, many production and recovery solutions have also been implemented to significantly reduce dust emissions, such as using a direct dust suction system from the compost bagging equipment to minimize dust dispersion in the factory. The unit has monitored electricity consumption through the total meter of the power company, and the lighting system mainly uses 50W LED lights to save energy. The natural lighting system implemented by the company is also quite good.

Mr. Ngo Chi Thang, Deputy Director of the Binh Duong Waste Treatment Branch, shared that the waste recycling plant has a capacity of 840 tons/day for household waste compost; an industrial and hazardous waste incinerator with a capacity of 320 tons/day; a medical waste incinerator with a capacity of 3 tons/day; a leachate treatment system with a capacity of 1,000 m3/day; industrial wastewater treatment with a capacity of 50 m3/day; a power generation capacity of over 2,000 kVA; recycling of ash and waste from self-compacting brick production with a capacity of 2,000 m2/day; recycling of sludge from water supply with a capacity of 100 tons/day to produce construction bricks; and industrial sludge drying ovens with a capacity of 100 tons/day. Especially for non-recyclable waste, it can still be utilized by collecting gas to create a power generation system with a capacity of up to 2,000 kVA. Thanks to investment, technology improvement, and waste treatment technique innovation to operate the power plant, it has contributed to increasing capacity and annual electricity production from waste treatment.

The unit has been and is constantly researching and applying advanced and environmentally friendly technologies in its production and business processes, including waste treatment of household, industrial, and hazardous waste; compost production, concrete production, building materials, recycled brick products, etc. with the desire to continuously improve the quality of life for local residents and contribute to the economic development of the province, providing favorable infrastructure for domestic and foreign investors.