Precast Design

Building industrial facilities requires speed, precision, and high flexibility. To meet these demands, APS offers Modular Design services, utilizing BIM technology to provide modern construction solutions and optimize the construction process from start to finish.

BIM technology allows us to design and simulate modular components in detail and with visual clarity. From planning, component production, to on-site assembly, every stage is strictly controlled to ensure synchronization and the highest accuracy. This not only shortens construction time but also reduces costs and minimizes material waste. We focus on delivering modern designs while also enhancing the long-term operational efficiency of the facility.

By choosing APS's Modular Design services, you will receive a comprehensive solution that helps reduce construction costs, accelerate implementation speed, and ensure the highest quality. Let us partner with you to bring pioneering and sustainable industrial projects to life. Contact APS today!

Advantages that assembly technology brings:

- Fast construction, reasonable price, high reusability

The most obvious advantage of prefabricated solutions is the high speed of construction because they are designed and manufactured in advance. Immediately after that, the prefabricated components are transported to the construction site and deployed for installation. The components of each component are optimally calculated and made from light and environmentally friendly materials. This makes the construction cost cheaper than other solutions.

When the purpose of use changes, the user can dismantle the entire project, move to another location, add or replace some parts to and re-assemble. That way, users can save costs.

- Environmental friendliness

The precast projects using non-toxic materials to virtually eliminate waste and environmentally damaging waste. Realizing structuralization and industrialization of construction, creating green buildings, environmental protection, low carbon and energy saving.

- The participation of the policy mechanism

The development of each type of technology is inseparable from the support of government policies, without corresponding policy support, it is very difficult to develop. Currently, some countries have tax incentives for prefabricated houses manufactured in factories to encourage environmental protection.

Some construction and assembly methods are being implemented:

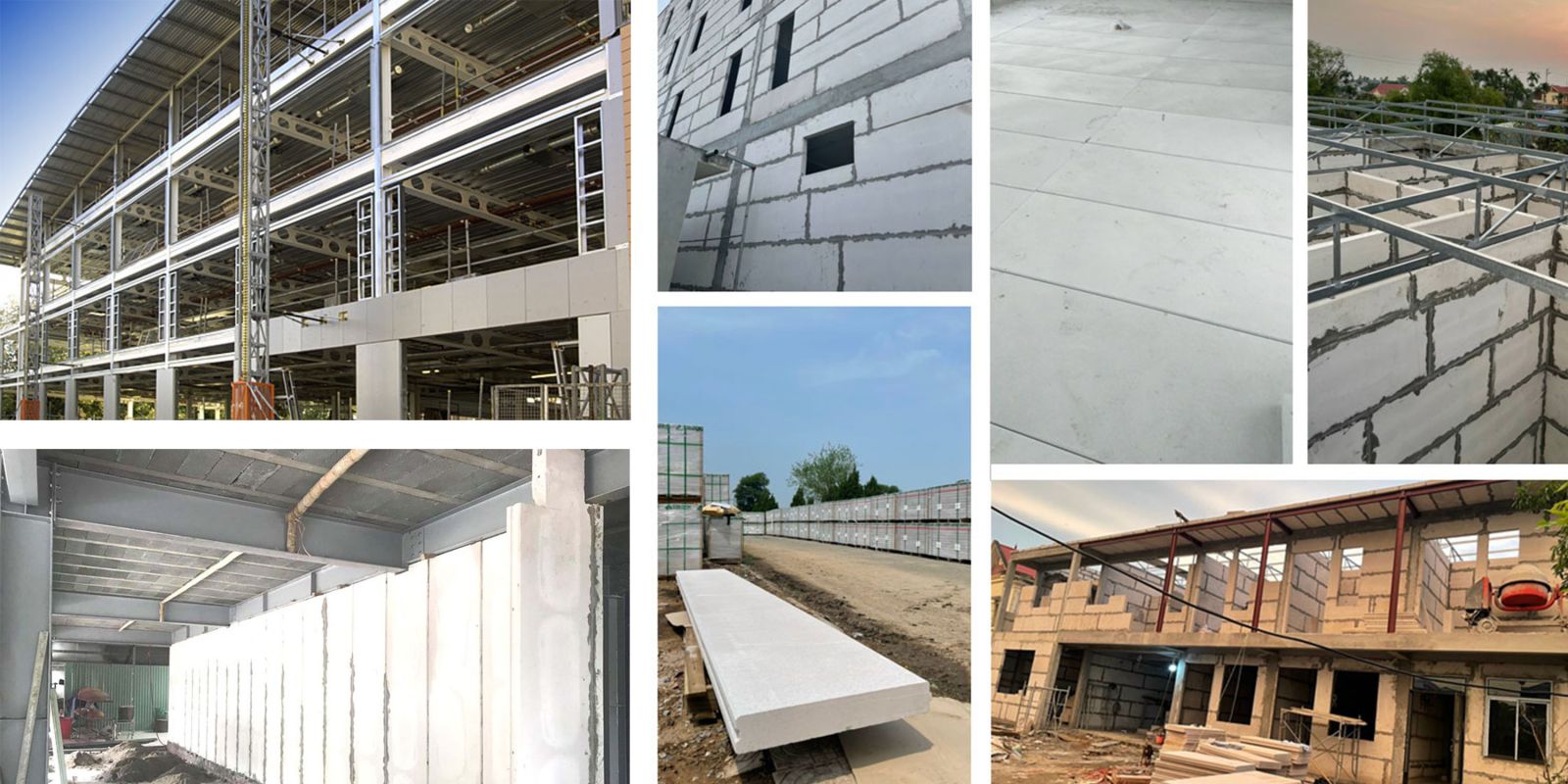

- Pre-Engineered Building Steel

Type of house using pre-engineered steel frame system and super light concrete panel floor to replace traditional concrete columns and ceilings. Meet all loads, durability requirements. More cost-effective than concrete house solution. Flexible in design, investors can unleash their creativity to create modern, impressive and unique works in their own style.

- Precast concrete technology house

All concrete components such as foundations, beams, columns, wall panels, floor slabs, etc. are precast at the factory. The components will then be erected at the site, Bolt connection. Use flexible materials and rubber gaskets to complete joints and joints.

As for the precast technology, while the foundation is being constructed at the construction site, the structural members of the body have been manufactured simultaneously at the factory. This allows to organize the construction more scientifically and shorten the time. Precast pre-stressed concrete components or using high-strength concrete allow large spans with slender progress to create large open spaces for the building.

- Modular house

This type of house is assembled and completed monolithically at the factory and then brought to the place by container truck and placed in the right position. This type of house is highly typical and difficult to customize according to the wishes of small investors. However, similar to other types of manufacturers in the factory, the product quality is well controlled, the construction time at the construction site is the shortest among all types of assembly.