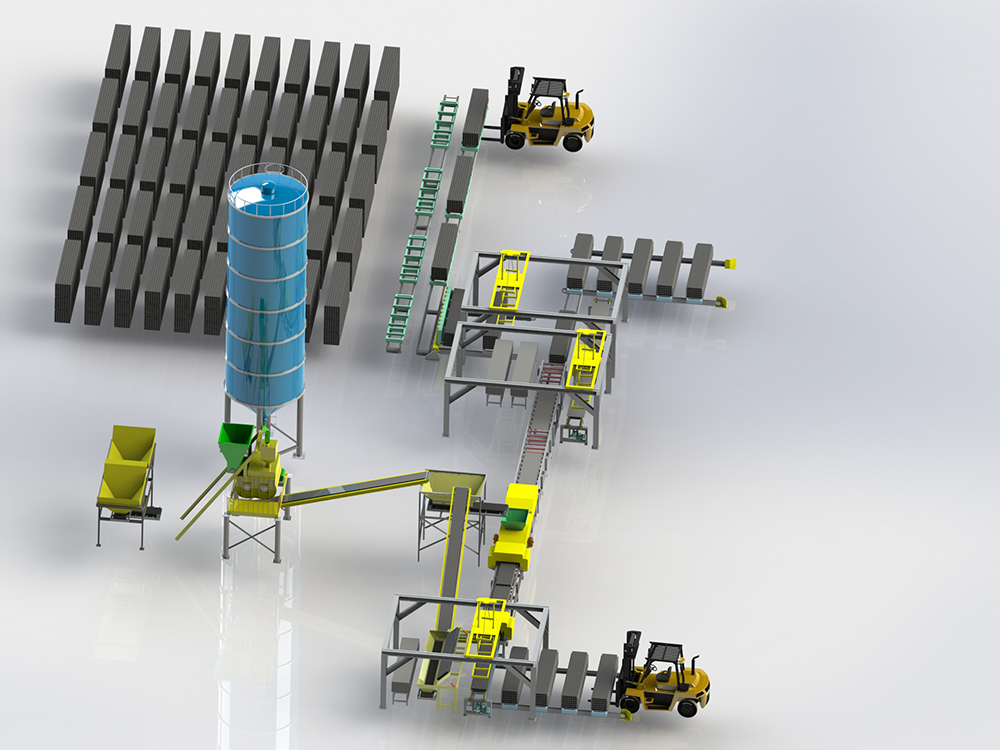

Factory Line Design

Line installation - The inevitable trend of modern production

Modern industry requires businesses to create a large number of products in a short time, and at the same time to meet product quality and standards. With a modern working line, the jobs are organized according to the professionalism of each movement, jobs with the same expertise will be combined into a work line by a group of workers, with a stable workforce and machinery.

The production that creates a product needs to comply with the unique characteristics of that product. The production stages will separate the components and functions of the product to complete a certain part of that product. Many stages are the output of the previous stage, and at the same time the input of the next, continuity is a prominent feature of the work line.

Installing modern production lines is an important basis for enterprises to catch up with the development trend of modern production, and at the same time improve production value and profits for enterprises

The characteristics of modern chains in the enterprise:

- High specialization

- Continuity

- Stability of the number of human resources

- Aggression (tense, urgency)

- Segmented but closely related activities

The trend of installing modern automation lines

With many outstanding advantages related to product quality, high working efficiency, increasing competitiveness for businesses. Currently, businesses are tending to install modern automated work lines with the orientation of reducing human involvement in production lines.

- Minimizing workers' muscular movements: a quality work line first of all needs to minimize the involvement of muscle power in the product creation process. This is a unique factor that distinguishes traditional production from modern production.

- Ensuring product quality: quality products are always the goal that businesses aim for, creating a competitive advantage for businesses, affirming brand value for businesses. Modern working lines will ensure product quality, meet standards and quality regulations.

- Automated operation rate: High automation ability helps enterprises to minimize workers in factories and production workshops. Thereby cutting costs related to people such as wages, insurance wages, labor accidents, sickness, bonuses...Current production lines often aim to reduce the number of workers and increase the automatic operation of the line.

- High working efficiency: working efficiency is evaluated in terms of operating ability and product creation time. The high-performance production line system has a short product creation time and can work continuously, the maintenance process does not take too much time.

- Low cost: Besides the cost of installing the line, the operating costs include many factors such as maintenance, maintenance, energy costs (gasoline, oil, electricity...) for the working line. In addition, the ability to work effectively on the line, minimizing excess materials as well as error-free products will help save costs for businesses.

- Optimal profit: the profit stream of the business needs to be optimized and effectively balance between investment, cost, profit and future growth

- Upgradability of production lines: market requirements continuously increase over time, products need to be continuously improved to meet the increasingly demanding needs of customers.Work lines need to be able to upgrade to meet actual needs, avoiding the need to completely replace to save costs for businesses.

Advantages of the line factory

Factory working in line will have many benefits related to labor productivity, ensuring work progress, and improving product quality. Inspection and supervision work is more convenient, optimizing costs and profits for businesses.

- Improve product quality: the work line helps each worker to ensure a stage with a high degree of specialization. This is the basis to improve the quality of output products. The stages of product creation are designed and operated according to a closed cycle, ensuring the creation of quality products, meeting output quality standards.

- Guaranteed progress: with high working efficiency, the work line can help businesses create a large number of products in a short time. It is a condition for businesses to sign urgent orders on schedule, improving competitive advantage in key moments.

- Inspection and supervision: the monitoring process plays a very important role during the working process of workers, in order to ensure work efficiency and create quality products.

- Profit optimization: increased labor productivity, guaranteed work quality, and quality output products are the top goals of enterprises. Installation of production lines is an ideal support for businesses to optimize costs and profits.

The working stages of the production line will separate activities and specific movements, so it is quite easy to check and evaluate the quality of work on each product . Create a basis for businesses to improve the quality of supervision, thereby improving productivity and quality of work.

Application of working line in production

Nowadays modern manufacturing industries all effectively apply working lines in production, in which there are prominent industries and fields such as:

- Automobile production and assembly: the automobile industry has grown strongly with high growth in recent years, requiring enterprises to expand production and improve production efficiency to meet market demand. Advanced automobile assembly and production lines help businesses improve working efficiency and meet the strict quality requirements in the auto industry.

- Household appliances production: household products with great demand are always fertile ground for production lines in Vietnam.The production lines with high working speed and quality standard products help enterprises to quickly expand the market and introduce new products to consumers.

- Food processing: food processing industries have high requirements on food safety and quality. The working line is designed to correspond to the working stages, creating a safe and quality food source.

- Other industries: textile, footwear, manufacturing and assembling electronic components....